2022-03-19 14:10:18

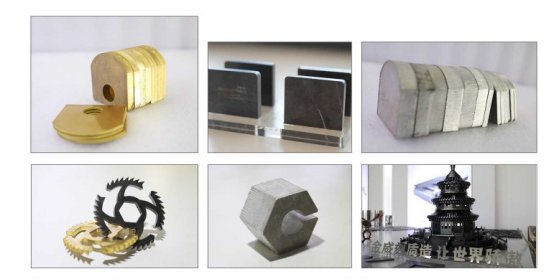

一. Common types of metals that can be cut

Carbon steel ,stainless steel, aluminum, brass etc. As for carbon steel ,now laser cutting machine can cut up to 60mm. As for stainless steel , our laser cut machine can cut up to 70mm, for aluminum, this fiber laser cutting machine can cut up to 60mm.

二. The factors that influence the laser cutting metal

1. The power of the laser

Actually, cutting capacity of the fiber laser cutting machine is mainly related to the power of the laser. At present, the most common powers in the market are 3000W.4000W. 6000W.8000W. high-power machines can cut thicker or stronger metals.

2. Auxiliary gas used in cutting

Secondly, there are auxiliary gases used in cutting. Common auxiliary gases are O2, N2 and air. Generally speaking, carbon steel is cut with O2, and the purity is required to be 99.5%. In the cutting process, the combustion-supporting oxidation reaction of oxygen can improve the cutting efficiency, and finally form a smooth cut surface with an oxide layer. However, when cutting stainless steel, due to the higher melting point of stainless steel, after considering the cutting quality and smoothness, N2 cutting is generally used, and the general purity requirement is 99.999%, which can prevent the incision from producing an oxide film during the cutting process. So that the cutting surfacte is White, and forms cut vertical grain.

Carbon steel is generally cut with N2 or air on high-power 10,000-watt machines. Air cutting saves cost, and the efficiency is twice as high as O2 cutting when cutting a certain thickness. For example, when cutting 3-4mm carbon steel, 3kw can cut this with air, 120000kw can cut 12mm with air. Gweike also provides various types of air compressors for customers to choose.

3. Influence of cutting speed on cutting effect

Generally speaking, the slower the set cutting speed, the incision is wider and uneven, the thickness that can be cut will be relatively larger. Do not always cut at the limit of the power, which will shorten the service life of the machine. When the cutting speed is too fast, it is easy to cause the melting speed of the incision to keep up, resulting slag hanging. Choosing the right speed when cutting will help to achieve a good cutting effect. Good material surface, selected lens, etc. will also affect the cutting speed.

4. The quality of the laser cut machine

The better the quality of the machine, the better the cutting effect, which can avoid secondary processing and reduce labor costs. At the same time, the better the performance of the machine tool and the kinematic performance of the machine tool, the less likely it is to vibrate during the cutting process, thereby ensuring good machining accuracy. The quality of the air circuit components of the machine will also affect the processing effect, and the pollution and leakage of the air circuit components should be avoided during use.

三. Widely use laser source

When it comes to lasers, the first thing that comes to mind is IPG. IPG lasers are mainly produced in the United States, Germany, and Russia. Lasers are divided into single-mode and multi-mode. Single-mode has advantages in cutting thin plates, and multi-mode has advantages in cutting thick plates. But IPG is relatively expensive compared to other lasers.In addition, Raycus laser is also a cost-effective choice. Generally, when cutting non-high-reflection materials, you can also choose Raycus .

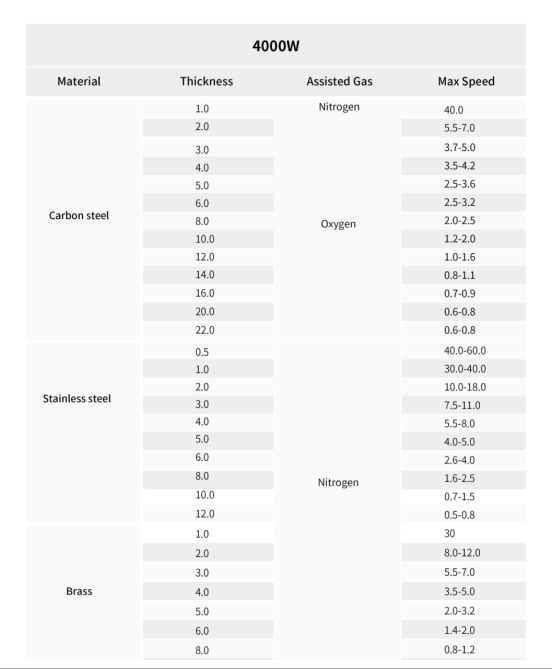

四. Thickness of 4KW cutting metal

Taking the cutting thickness of IPG laser as an example, under normal circumstances, 4KW can cut carbon steel up to 22mm, stainless steel up to 12mm, brass up to 10mm. The cutting parameters can be obtained by contacting our staff.