Machine Show

Cutting Show

Customer Voice

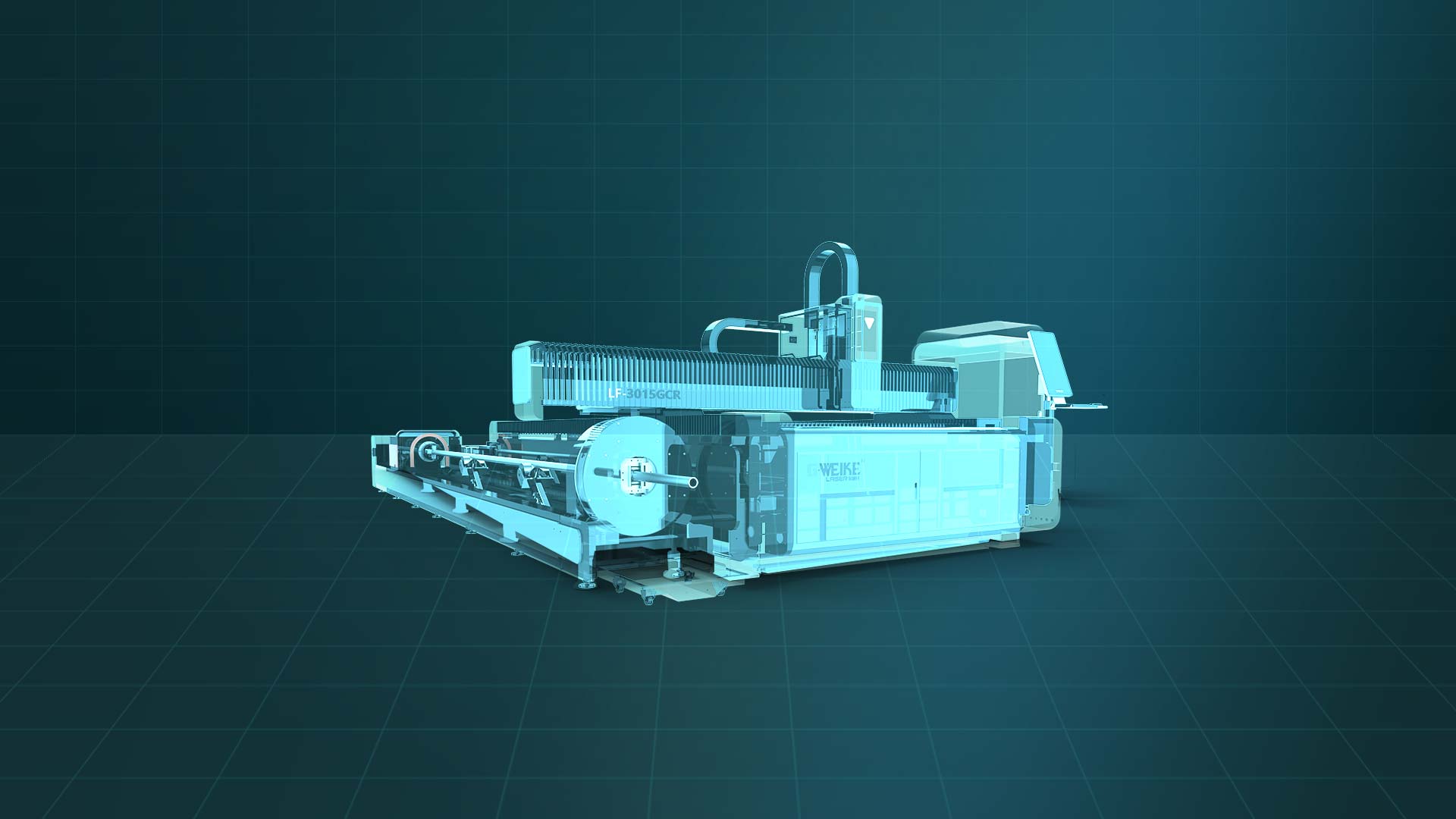

G.WEIKE GCR series fiber laser cutting machine can not only cut metal plates,but also metal pipes. It has many uses and can save the space of more than 50%,which effectively improve productivity.

It adopts an up and down exchange platform;The converter is responsible for controlling the exchanging motor;The machine is able to finish the platform

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed.

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life span of the fiber laser cutting machine work bed will be doubled.

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

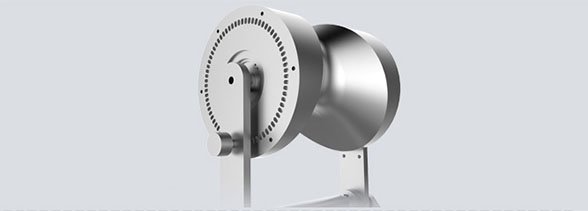

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Dust-proof design to prolong the lifespan of the electrical componen

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

G·WEIKE fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and German Neugart reducer. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 10 years.

Widely used in the processing of metal tube structure, advertising board, spring coil slic, textile machinery parts, kitchen utensils, car, machinery, elevator, Hv/lv electrical ark production, electric parts, subway line spare parts, etc. Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum- plating zinc plate, copper and other metals.

Fiber Laser Cutting Machine