2019-11-16 13:54:44

Summer is the high incidence season of laser failure. In order to avoid loss of condensation, please follow the instructions below:

When ambient temperature is above 30℃, chiller water temperature setting:

Low temperature water: 27℃

high temperature water: 30℃。

When it has air conditioner in working room, adjust room temperature during 23-25℃ dehumidification. Keep humidity below 50%。

Low temperature water: 25℃

high temperature water: 30℃

The chiller must use distilled or deionized water. It is recommended to change every 15 days in summer, and every 2 months in other seasons.

Before you start the machine, you need to pay attention to the following steps:

1.First of all, keep the water chiller off, turn on the laser source power supply, then keep the air conditioner in control cabinet on for about two hours.

2.When turn on the laser source power supply for two hours, turn on the water chiller. adjust water temperature to be predetermined, and then start the laser light output.

3.The shutdown order of fiber laser cutting machine is: Turn off the chiller at first, then turn off the laser. Strictly forbidden operation is the laser off but the chiller is on.

Pay attention: For laser power above 3000W, it is necessary to install an air-conditioner. If the air conditioner is not installed, it is forbidden to use machine, otherwise, the loss will be borne on yourself.

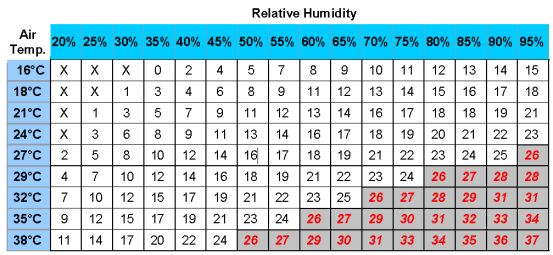

Reference table

The dew condensation temperature on the different humidity, the temperature setting of the water chiller must be higher than the dew point temperature.