Machine Show

Cutting Show

Customer Voice

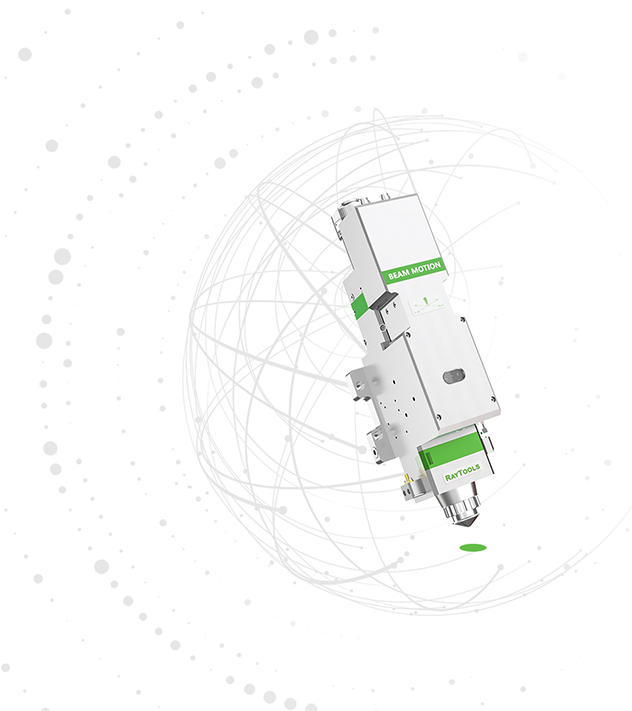

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

The smoke produced by cutting can be filtrated inside, it’s non-polluting and environmentally; friendly.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

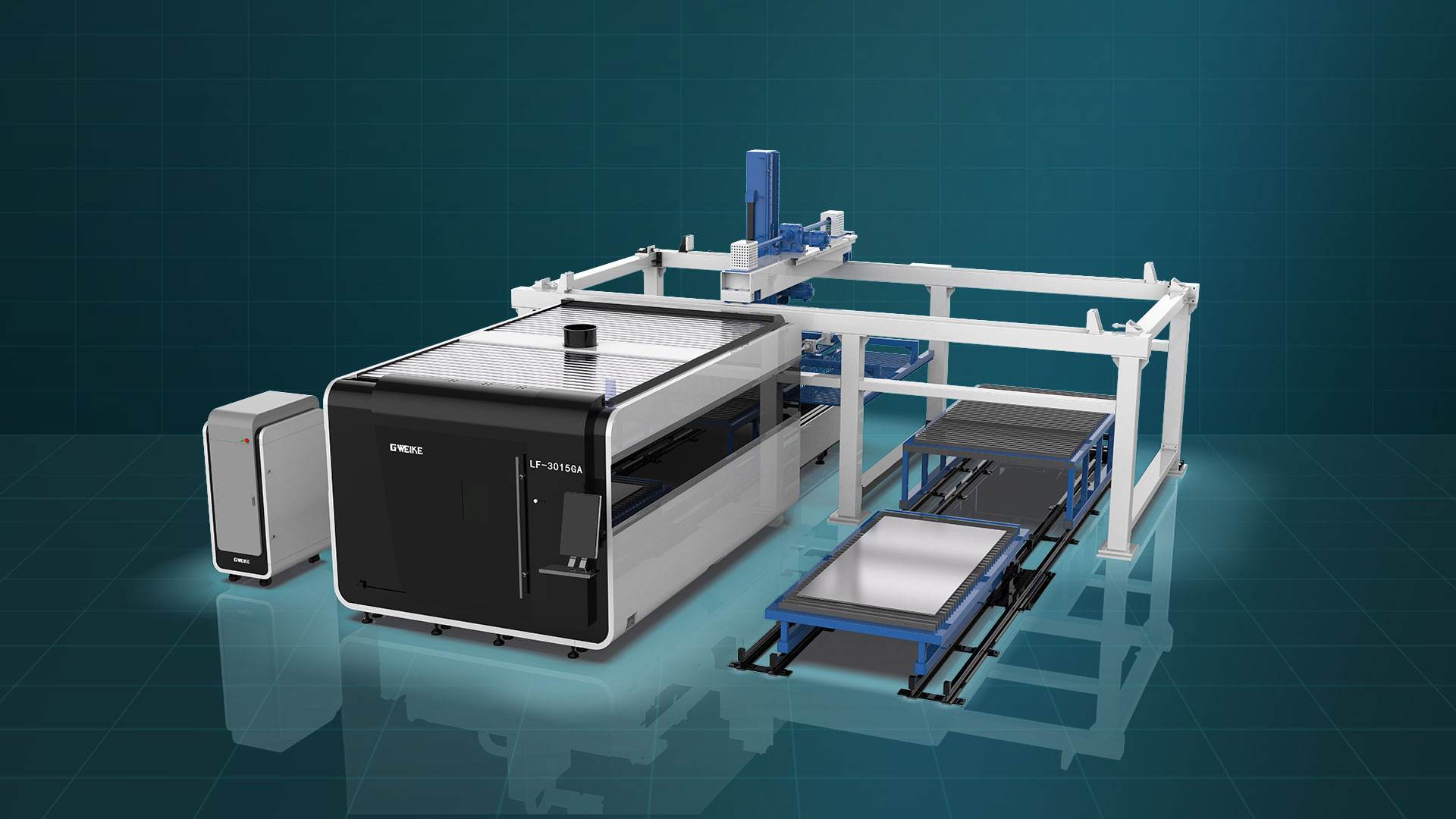

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed.

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life span of the fiber laser cutting machine work bed will be doubled.

GWEIKE laser cutting machine YLS-CUT series high power fiber laser of IPG. Powerful cutting ability with stainless steel, aluminum and other metal materials, cutting thickness is up to 40mm.Long Service Life.

The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely.

Fiber laser source can produce excellent beam quality,finer cutting lines,higher working efficiency and better machining quality.Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation.

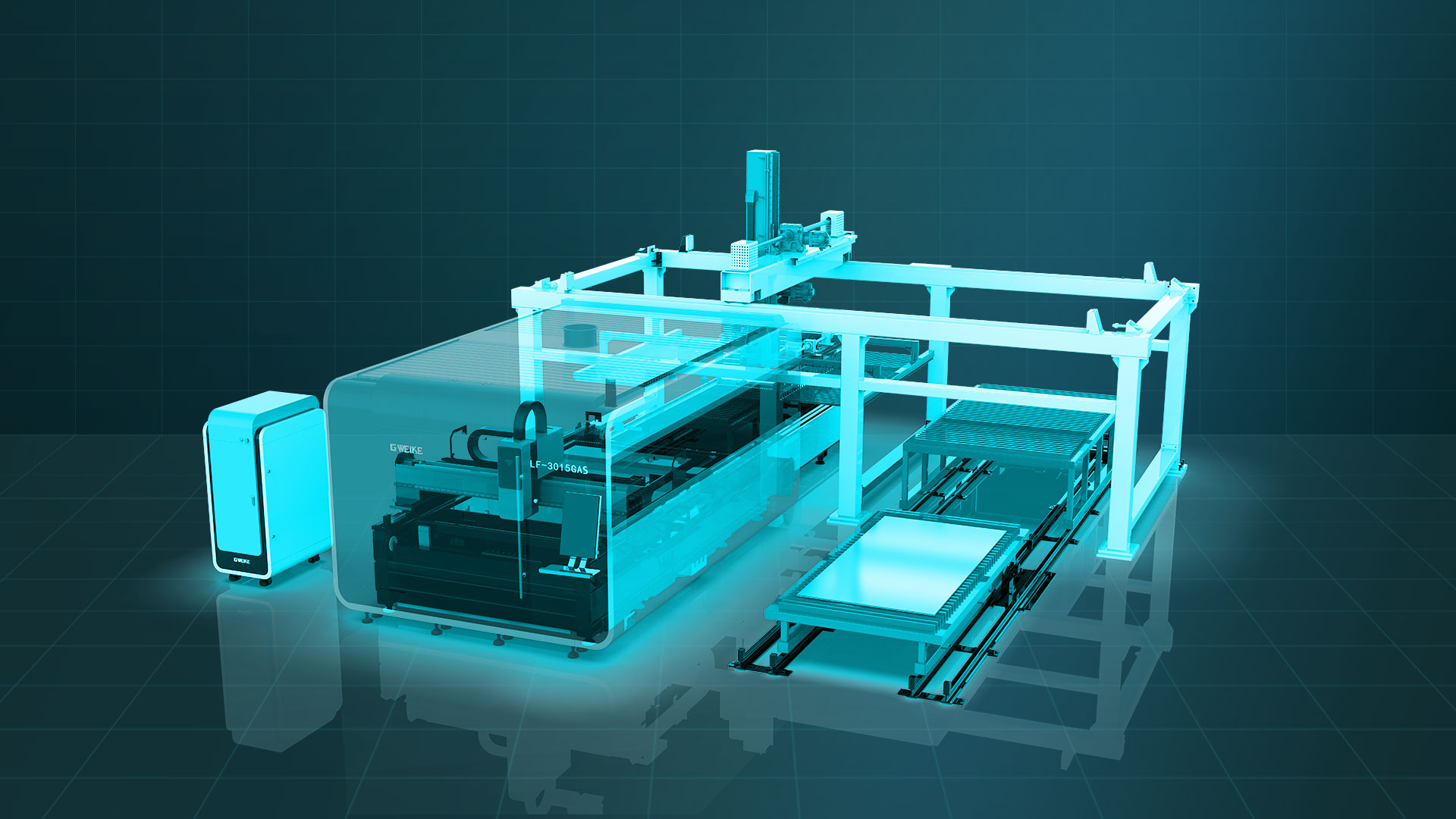

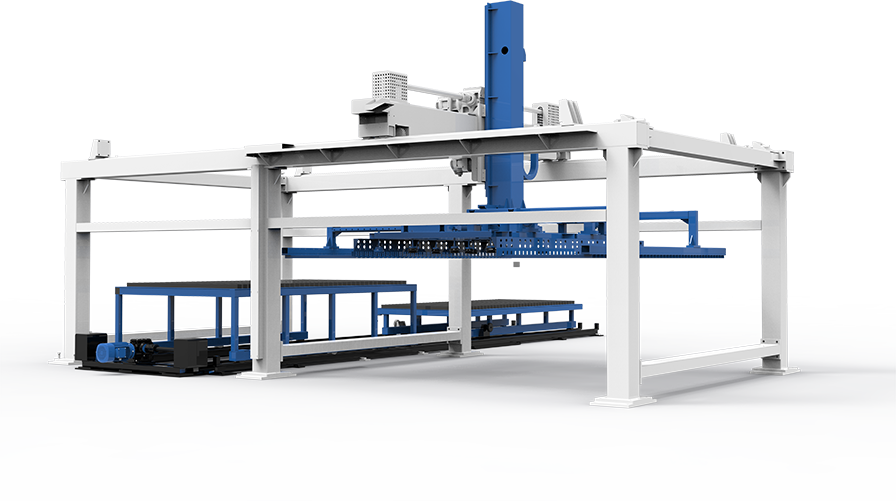

Gantry type automatic loading and unloading structure, high stability, high safety factor, customers can choose not to lay foundation, easy to install, with CE certification.

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolongthe lifespan of the electrical components.

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Fully enclosed design; the observation window adopts European CE standard protective glass; the smoke generated by cutting is internally filtered, and the emission is up to the standard, without pollution;

SMC vacuum suction cup, with long mission, international brand, high safety factor action sensitivity, good effect of layered thickness measurement.

In the processing process, each dead corner area can be monitored at any time, the process can be controlled.

LF3015GAS fiber laser cutting machine can carry up to 8000W laser power, so cutting some thick plate, it is a very good choice. For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing. Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

| Machine model | 3015GAS |

| Max. loading and unloading size | 3000 * 1500mm |

| Min. loading and unlading size | 1200*1000mm |

| Max. loading weight | 300Kg(Option) |

| Loading metal plate thickness | 0.8-8mm |

| Cycling time | 120s(can Adjustment) |

| Total power of servo motor | 10.2Kw |

| Gas pressure | 0.55MPA |

| System weight | 5600Kg |

| System size | 8380*7190*3800mm(length*width*height) |

G.weike 레이저 글로벌 제조를 선도하다